Provide trusted solutions to build, renovate and repair homes around the world, with confidence from start to finish, while demonstrating an intense desire to help others succeed.

NO MATTER WHO YOU ARE, WE HAVE YOU COVERED

Featured Projects

Trusted Brands

Resources + Support

person

Ask the Expert

Whether you have a question or comment, we would like to hear from you.

Contact Us

play_arrow

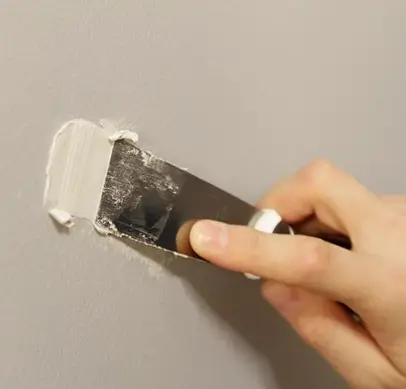

How to Caulk and Seal A Bathroom

A new bead of sealant will provide protection against water damage and help your bathroom look brighter, fresher and cleaner. Learn how to use Kwik Seal Ultra to seal cracks in your bathroom, its breakthrough innovation repels water, dirt and stains, is backed by a Lifetime Mold & Mildew Resistance Guarantee and is shower ready in just four hours.

View All How To'sOur Mission